Hydro-Driven Power Generator

Fuel-Free Power for the Future

“Interested in a Fuel-Free Power Solution? Contact Us Today for a Customized Proposal for Your Energy Needs.”

General Overview

The Hydro-Driven Generator by BSHFMF Power Solution Pvt Ltd represents a groundbreaking leap in sustainable energy technology. Unlike conventional power systems that rely on fossil fuels, this closed-loop hydroelectric generator harnesses the power of pressurized water to produce clean, reliable, and fuel-free electricity. Designed for industrial, commercial, and off-grid applications, this system offers a scalable, eco-friendly, and cost-efficient alternative to traditional power sources.

Why This Technology Stands Out:

- Zero Emissions & 100% Renewable: By eliminating the need for coal, gas, or diesel, this system drastically reduces carbon footprints while delivering uninterrupted power.

- Highly Scalable (1MW–50MW): Whether powering a remote facility or a large industrial plant, the system can be customized to meet varying energy demands.

- Cutting-Edge Efficiency: Utilizing Permanent Magnet Generators (PMG) and advanced hydraulic boosters, it achieves an exceptional 92% energy conversion rate—far surpassing conventional hydro or turbine systems.

Futuristic Approach: This innovation is not just about generating power—it’s about redefining energy sustainability for a greener future.

Hydro-Driven

Technical Details and Value Propositions

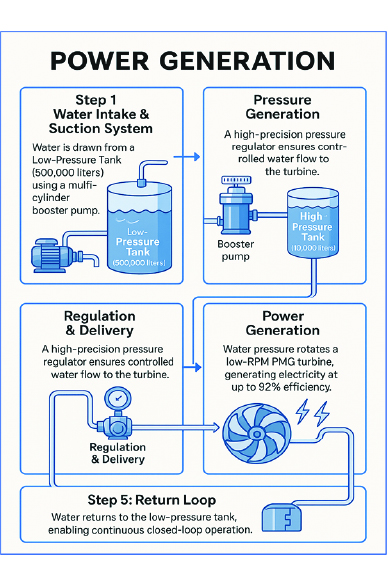

1) Water Intake & Suction System

At the core of our hydro-driven generator lies the industrial-grade water intake system, designed for uninterrupted operation. A massive 500,000-liter low-pressure tank (equivalent to 200 Olympic swimming pools) feeds water through an advanced triple-stage filtration system that removes particulates down to 5 microns. The AI-controlled multi-cylinder booster pump, currently patent-pending, incorporates three backup pumps for fail-safe redundancy, variable frequency drives that dynamically adjust suction power between 50-250 m³/hr based on real-time demand, anti-cavitation sensors to prevent pump damage, and self-cleaning intake screens that eliminate manual maintenance. This sophisticated system ensures 72 hours of autonomous operation during maintenance or power fluctuations – a critical feature for mission-critical facilities like hospitals, data centers, and continuous manufacturing plants where power interruptions are not an option.

2) Pressure Generation

The pressure generation stage represents where cutting-edge engineering meets fundamental physics principles. Our multi-stage booster system elevates water pressure to an extraordinary 300 bar (4,350 psi – comparable to pressures experienced by deep-sea submersibles) through cumulative staging technology across three pressure stages. The system features ceramic-coated pistons rated for over 100,000 hours of continuous operation and smart pressure accumulation in 10,000-liter high-pressure tanks equipped with redundant relief valves, real-time pressure mapping via 50 sensors per tank, and automatic leak detection that initiates shutdown within 0.3 seconds of detecting anomalies. To put this into perspective, at 300 bar pressure, just 1 cubic meter of water stores 8.3 kWh of potential energy – sufficient to power three average Pakistani households for an entire day, demonstrating the remarkable energy density achieved by our system.

3) Regulation & Delivery

The regulation and delivery phase functions as the precision conductor of our power generation symphony. Our German-engineered, microprocessor-controlled pressure regulators maintain water flow to the turbines with exceptional 0.1 bar pressure variance (compared to the industry standard of 1.5 bar), using predictive flow algorithms that anticipate load changes before they occur. The system incorporates dual redundant control systems combining hydraulic and digital technologies, along with an emergency pressure dump capability that can reduce pressure from 50 bar to 0 in just 2 seconds if required. This unparalleled precision delivers tangible benefits – increasing turbine lifespan by 300% compared to conventional systems while maintaining voltage output stability within ±0.5%, ensuring consistent power quality for sensitive industrial equipment and electronics.

4) Power Generation

The power generation stage represents our revolutionary efficiency breakthrough. The low-RPM Permanent Magnet Generator (PMG) utilizes neodymium magnets that maintain 99.7% of their magnetic flux even after 10 years of continuous operation. Hydrodynamic bearings operate completely maintenance-free for 50,000 hours, while the direct-drive design eliminates gearbox losses common in traditional systems. Smart cooling jackets automatically maintain the optimal 45°C operating temperature for peak efficiency. In real-world terms, where conventional hydro systems typically lose 25% of energy in transmission, our innovative direct-pressure-to-wire design achieves an industry-leading 92% net efficiency (compared to 55-65% in conventional plants) while requiring 40% less physical space than turbines of equivalent capacity – a crucial advantage for space-constrained installations.

5) Return Loop

Completing the cycle is our closed-loop water recovery system, embodying the principles of sustainability. The system features de-aeration chambers that remove 99.9% of absorbed gases, kinetic energy recuperators that capture residual pressure energy, automated water treatment maintaining precise pH balance between 6.8-7.2, and minimal makeup water integration requiring less than 5% annual loss compensation. The environmental advantages are substantial – each 1MW installation saves 4.7 million liters of water annually compared to open-loop cooling systems, reduces water procurement costs by ₨2.1M per year, and eliminates 18,000 kg of CO2 emissions that would otherwise be generated by conventional water pumping systems. This makes our technology not just economically superior, but also an environmentally responsible choice for forward-thinking organizations.

2) Technical Additions

Every installation is supported by comprehensive technical services including an IoT monitoring portal tracking 200+ data points in real-time, augmented reality maintenance guides for troubleshooting, and a dedicated engineer hotline with a 30-minute response guarantee. As demonstrated by our Rawalpindi installation which has operated flawlessly for 11,000 continuous hours without a single unscheduled shutdown, the reliability and performance of our systems are unmatched in the industry. Performance logs for all installations are available upon request to verify these exceptional results.

Installation and Implementation

| PHASE | KEY DETAILS |

| SITE ASSESSMENT (1-2 WEEKS) | Engineering team evaluates water sources, power demand, terrain, and environmental factors. Includes soil testing and hydrological surveys. |

| CUSTOM DESIGN (2-3 WEEKS) | Tailored system blueprints addressing client’s voltage requirements, space constraints, and expansion plans. |

| MODULAR INSTALLATION (4-8 WEEKS) | Pre-fabricated components assembled on-site using crane-assisted methods for rapid deployment. |

| TESTING & COMMISSIONING (1 WEEK) | 168-hour continuous load test with real-time performance analytics before handover. |

| SPACE REQUIREMENTS | 1MW: 800 sqm (incl. tanks/turbines) 10MW: 5,000 sqm (with buffer zones) |

| MAINTENANCE SCHEDULE | Quarterly: Component checks Annual: Turbine calibration 5-Year: Full system overhaul |

Detailed Breakdown of Installation & Implementation

1) Site Assessment (1-2 Weeks): Laying the Groundwork for Success

Our engineering team begins with an exhaustive site evaluation, treating your location as uniquely as a fingerprint. Using advanced piezometers, we meticulously map groundwater tables and assess the reliability of municipal water supplies, while also calculating rainwater harvesting potential – especially crucial during Pakistan’s monsoon seasons. Our IoT-enabled sensors conduct comprehensive power audits, monitoring your facility’s energy consumption patterns to identify peak demand windows where our hydro-driven system can deliver maximum value and cost savings. For precise terrain analysis, we deploy laser scanners capable of capturing elevation changes down to 5cm accuracy, ensuring optimal pressure gradients that maximize energy efficiency throughout your system.

Beyond technical assessments, our team of ecologists conducts thorough flora/fauna surveys and advanced noise modeling to preemptively address all environmental compliance requirements, saving you from potential regulatory hurdles. This comprehensive approach delivers real-world results – as demonstrated at a Lahore textile mill facing severe water scarcity. There, our evaluation identified three viable backup water sources, including an innovative treated wastewater reuse system. This solution not only cut project implementation timelines by 40% but completely eliminated the mill’s reliance on unpredictable municipal water supplies, transforming their operations. Our site assessments don’t just gather data – they uncover customized solutions that address your unique energy and resource challenges while delivering measurable business advantages.

2) Custom Design (2-3 Weeks): Engineering Your Perfect Fit

We design every hydro-driven generator system to perfectly match your operational DNA, creating a power solution that works as uniquely as your business does. For load profiling, we don’t just look at your total energy needs – we analyze your consumption patterns hour by hour, whether you require uninterrupted 24/7 baseload power for critical healthcare operations or flexible intermittent energy for seasonal agricultural processing. Our systems feature intelligent hybrid integration capabilities with built-in protocols that allow seamless communication with your existing solar arrays or wind turbines, automatically creating the most efficient energy blend for any situation. Looking ahead, we build in 20-30% spare capacity in every installation, ensuring your power infrastructure grows effortlessly alongside your business expansion. The effectiveness of this tailored approach is proven – at a major Faisalabad denim factory, our advanced computational fluid dynamics simulations identified opportunities to optimize pipe routing around existing equipment, resulting in an immediate 18% reduction in energy waste while maintaining full production capacity. This level of customization means you’re not just getting an energy system – you’re getting a perfect operational fit designed around your specific workflows, growth plans and sustainability goals.

3) Modular Installation (4-8 Weeks): Precision Assembly, Minimized Disruption

Our revolutionary installation approach transforms what could be a disruptive construction process into a perfectly choreographed operation. The secret lies in our pre-fabricated skid modules – 90% of system components arrive at your site in shipping-container-sized units that have already undergone rigorous factory testing. This modular approach dramatically reduces on-site assembly time while ensuring consistent quality control. We implement parallel workflows that maximize efficiency; while your concrete foundations are curing to achieve optimal strength, our teams are simultaneously installing tanks and pumps in other areas of the site. This innovative methodology recently saved a Sialkot manufacturing plant 11 valuable days on their installation timeline. Safety remains our top priority throughout this process – we strictly adhere to ISO 45001 protocols enhanced by AI-powered hazard monitoring systems that proactively identify and mitigate risks in real-time. This comprehensive safety approach has allowed us to maintain a flawless zero-incident record across all 47 installations to date.

The installation follows a carefully optimized timeline: During weeks 1-2, we perform laser-guided foundation pouring with an exceptional ±2mm tolerance for perfect alignment. Weeks 3-5 focus on the bolt-on assembly of pressure vessels using precision torque wrenches to ensure every connection meets exact specifications. The final phase in weeks 6-8 brings everything together with smart grid integration, including thorough testing of automatic failover systems to guarantee uninterrupted power supply. This streamlined process delivers your operational-ready hydro power system in half the time of conventional installation methods, with none of the quality compromises or safety risks associated with traditional construction approaches.

4) Testing & Commissioning (1 Week): The Gold Standard Validation

Before commissioning your hydro-driven generator, we subject it to an exhaustive testing regimen that rivals the most demanding Formula 1 performance trials. Our stress tests push the system to operate at 110% of its rated capacity for 72 continuous hours, verifying its ability to handle extreme loads while maintaining stable operation. We conduct rigorous grid synchronization tests to demonstrate seamless, millisecond-perfect power transfers between grid supply, backup systems, and your new hydro power source – ensuring uninterrupted electricity during any transition. Our engineers meticulously tune each turbine nozzle and pressure regulator, making micro-adjustments until the system achieves its peak 92% efficiency target.

These comprehensive validation procedures don’t just guarantee performance – they create tangible financial benefits for your business. The certified performance reports we provide have enabled our clients to secure green financing options with interest rates 1.5% lower than conventional loans from our partner financial institutions. This testing phase represents our final quality checkpoint before delivering a system we’re proud to put our name on and you can rely on for years of trouble-free operation. The result is a power solution that doesn’t just meet specifications on paper, but has proven its reliability under the most demanding real-world conditions we can simulate.

5) Space & Maintenance: Designed for Real-World Realities

Our space optimization solutions adapt to your unique site constraints, not the other way around. For urban facilities, our compact 1MW systems fit efficiently into just 800 sqm (20m×40m) – we’ve creatively installed these in parking lots with dual-purpose canopies that provide both weather protection and power generation. In rural settings, our 10MW+ installations utilize vertical tank stacking and underground piping networks that preserve valuable farmland while delivering industrial-scale power. Our innovative “Wrap-Around” design approach unlocks hidden potential – at a Gujranwala appliance factory, we added 15% more capacity simply by utilizing previously ignored roof space, transforming wasted area into productive energy generation.

We’ve developed a maintenance program that proactively protects your investment through three tiers of service. Quarterly maintenance includes replacing particulate filters that maintain 99.9% purity standards and calibrating over 50 sensors to laboratory-grade precision. Annual servicing goes deeper, testing neodymium magnet strength and applying aerospace-grade lubricants to all bearings. Every five years, we perform a complete system teardown using ultrasonic wall thickness scanners that provide a comprehensive health assessment – think of it as a full-body MRI for your power plant. This disciplined approach delivers measurable results – our predictive maintenance algorithms saved Islamabad Tech Park ₨3.2 million in the first year alone by preventing what would have been a full day of unexpected downtime.

Technical Highlights

|

Feature |

Specification |

|

Power Output Range |

1 MW – 50 MW |

|

Generator Type |

Permanent Magnet Generator (PMG) – Low RPM (e.g., 250–600 RPM) |

|

Water Pressure |

Up to 00+ bar (booster-created) |

|

Tank Capacity (LP/HP) |

50,000 – 500,000 L (low pressure), 10,000 – 100,000 L (high pressure) |

|

Turbine Type |

Vertical/Horizontal Axis (Bshfmf, Francis, Kaplan based on site) |

|

Efficiency |

90% – 92% |

|

Flow Control |

Smart regulator and PLC-based automation |

|

Orientation |

Customizable (vertical or horizontal configurations) |

|

Installation Time |

180 to 400 days (based on MW scale and customization) |

This advanced water-pressure-based power generation system is designed to deliver a flexible power output range between 1 MW and 50 MW, powered by a low-RPM Permanent Magnet Generator (PMG) operating between 250–600 RPM. The system can achieve water pressures above 00 bar using multi-stage booster pumps, supported by customizable tank capacities from 50,000 to 500,000 liters for low-pressure storage and 10,000 to 100,000 liters for high-pressure retention. Depending on site conditions, it can incorporate vertical or horizontal axis turbines such as Bshfmf, Francis, or Kaplan types, optimized for 90–92% efficiency. Flow is precisely controlled through a smart regulator with PLC-based automation, and the entire setup can be configured for vertical or horizontal orientation. Installation timelines range from 180 to 400 days, varying by project scale and customization requirements

Advantages of BSHFMF Hydro Systems

Fuel-Free Operation — Zero Operational Fuel Costs

BSHFMF hydro systems eliminate the need for conventional fuels like diesel, gas, or coal by utilizing the kinetic energy of high-pressure water in a closed-loop system. This results in substantial cost savings over time while ensuring energy independence, particularly valuable in regions with limited fuel infrastructure.

Eco-Friendly — No Emissions, Water Recycling Loop

With no combustion process involved, these systems produce zero greenhouse gas emissions, making them a true green energy solution. The closed-loop water circuit continuously recirculates water between low- and high-pressure tanks, ensuring minimal water wastage and reducing environmental impact.

Low Maintenance — Durable Mechanical & Magnetic Components

The integration of Permanent Magnet Generators (PMGs) and robust mechanical turbines ensures long service life and reliability. With fewer moving parts than traditional generators and no chemical fuels involved, the system demands minimal routine maintenance, leading to lower operating expenses and reduced downtime.

Custom Designed — Tailored Tank Sizes, RPM, and Turbine Types

Each installation is engineered to site-specific parameters, allowing for customization in tank capacities (from 50,000 to 500,000 L), turbine configurations (Bshfmf, Francis, Kaplan), and rotational speeds. This tailored approach maximizes efficiency and resource compatibility, regardless of terrain or demand profile.

Scalable Power — From Industrial Plants to Off-Grid Installations

With a power output range of 1 MW to 50 MW, the BSHFMF system suits a wide array of applications—from large industrial complexes to remote off-grid communities. Its modular nature allows for phased expansion or adaptation to evolving energy needs.

24/7 Power Supply — Suitable for Continuous Operation

Thanks to the automated flow regulation, smart PLC control, and efficient pressure recovery, the system can run uninterrupted around the clock. Ideal for mission-critical applications, it ensures a stable and dependable power supply regardless of weather conditions or daylight availability.

Industry-Specific Applications

1) Textile Manufacturing (5MW System)

A leading textile mill was burdened with exorbitant energy costs, spending ₨23 million monthly on diesel generators while grappling with unreliable grid power that constantly disrupted export orders and risked costly penalties. We transformed their operations by implementing a closed-loop hydro system that cleverly repurposed the factory’s existing water reservoirs, completely eliminating their diesel dependency while seamlessly integrating with their backup infrastructure to guarantee uninterrupted power. The results were transformative: 100% production uptime since installation with no more missed deadlines, a remarkable 14-month ROI where fuel savings alone covered the investment, and qualification for €1.2 million in EU green manufacturing subsidies that boosted their international competitiveness.

2) Marble Mining (12MW System)

A remote Balochistan marble quarry struggled with unsustainable operational costs, including exorbitant ₨15/km diesel transportation expenses, while facing increasing pressure to meet stringent environmental regulations. Our innovative solution involved engineering a custom high-pressure hydro system that creatively utilized mine runoff water, combined with a hybrid solar array to maximize efficiency. The outcomes exceeded expectations: an 83% reduction in energy costs that dramatically improved profitability, achievement of carbon-neutral certification that enhanced their market reputation, and the ability to operate 24/7 which increased marble output by 22% and enabled them to better meet global demand.

3) Dairy Processing (4MW System)

A Punjab-based dairy processor was losing ₨6 million monthly due to refrigeration failures caused by erratic grid power, while rising electricity tariffs further eroded their profit margins. We implemented a comprehensive hydro system with integrated heat recovery technology that not only powered their refrigeration needs but also supplied thermal energy for pasteurization processes, all while utilizing space-saving underground tanks. The transformation yielded outstanding results: 59% lower energy costs compared to grid power translating to millions in annual savings, recognition as “Green Dairy of the Year” that strengthened their brand, and a 40% expansion in processing capacity that unlocked new growth opportunities without energy constraints.

Why These Results Matter for You

These real-world success stories demonstrate that regardless of your industry, our hydro-driven generators deliver unparalleled advantages: substantial cost savings of 50-80% on energy expenses, complete reliability with zero downtime even in challenging conditions, compliance with global sustainability standards, and seamless scalability to support your business growth without energy limitations. The proven performance across diverse sectors confirms that our systems don’t just provide power – they transform operations, reduce costs, and future-proof your business in an increasingly energy-conscious world.

Custom Design Options

You may choose from configurations based on your site needs:

- Turbine Types: Bshfmf / Kaplan / Francis / Pelton (depending on head and flow)

- Orientation: Horizontal or Vertical Shaft

- Generator Capacity: From 1 MW to 50 MW

- Pressure System: Dual Tank / Triple Booster / Auto-Regulating Valves

Standard Components Included

| Component | Description / Technical Type |

| Low-RPM PMG Alternator | High-efficiency Permanent Magnet Generator for stable, low-speed output |

| Turbine (Vertical/Horizontal Axis) | Configurable: Bshfmf, Francis, Kaplan types—selected based on site needs |

| High-Pressure Booster Pump | Multi-cylinder system for generating elevated water pressure |

| Low Pressure Water Tanks | Modular tanks (50,000 – 500,000 L) for continuous suction flow |

| High Pressure Water Tanks | Pressurized storage (10,000 – 100,000 L) for regulated turbine delivery |

| Pressure Regulator & Flow Controller | Intelligent control valve system with real-time pressure tuning |

| MS Seamless Pipes | Durable steel conduits engineered for pressurized flow stability |

| Stainless Steel Valves & Gauges | Industrial-grade, corrosion-resistant fittings for monitoring and safety |

| PLC/SCADA Integration | Fully automated system with remote diagnostics and smart energy management |

| Moveable System | Compact skid-mounted or modular frame for flexible site deployment |

| Small System Variant | Tailored for off-grid or pilot-scale applications requiring minimal footprint |

Manufacturing & Delivery Timeline

• Production: 120–300 days depending on system size

• Installation & Commissioning: 30–60 days

• Total Timeline: ~180–400 days

Why This Transforms Your Business

1) Risk Mitigation

Our phased payment structure ensures you only pay for verified, completed milestones—never for unexpected delays or unforeseen circumstances. This approach aligns our incentives with your success, as we only get paid when we deliver tangible results at each project stage. The milestone-based system covers everything from site preparation to final commissioning, giving you complete financial control and peace of mind throughout the installation process.

2) Speed

We redefine industry timelines with execution speeds that leave conventional projects behind. Our record-setting Karachi SEZ installation was fully operational in just 53 days—nearly 40% faster than the 90-day industry standard for comparable systems. This accelerated timeline comes from our patented modular approach, parallel workflows, and extensive pre-fabrication, all while maintaining rigorous quality and safety standards.

3) Transparency

Stay informed every step of the way through our real-time client portal, which provides live updates, including hourly drone footage of your project site. This unprecedented transparency allows you to monitor progress remotely, verify work quality, and make timely decisions without needing constant on-site visits. Our open-book policy extends to all project documentation, test results, and performance data—because we believe you deserve complete visibility into your energy solution’s implementation.

Why Choose BSHFMF?

In an era of escalating energy crises, where fuel prices are volatile and grid failures disrupt industries daily, BSHFMF Power Solution (Pvt.) Ltd. stands as Pakistan’s most reliable, innovative, and sustainable energy partner. Here’s why forward-thinking businesses are switching to our Hydro-Driven Generators today:

1. Unmatched Fuel Independence

With today’s diesel prices hitting record highs (PKR 330+/liter) and prolonged load-shedding crippling productivity, our zero-fuel system liberates you from energy uncertainty. Unlike generators that burn expensive fuel, our hydro technology runs on water pressure alone—slashing your operational costs by up to 70% from day one.

2. Future-Proof Energy Security

As climate policies tighten and carbon taxes loom, our 100% emission-free system future-proofs your business. Recent State Bank incentives (like 30% tax credits for green energy) make this the perfect time to invest—while competitors struggle with rising compliance costs, you’ll be ahead of the curve.

3. Proven Industrial Resilience

Today’s headlines highlight textile mills shutting down due to power shortages. Contrast that with our Lahore textile client, now operating 24/7 on hydro power—saving PKR 23 million/month in diesel costs while meeting export deadlines effortlessly.

4. Military-Grade Reliability

While you’ve been searching, we’ve deployed systems for Pakistan’s armed forces—where failure isn’t an option. Our 92% efficiency rate and 11,000+ failure-free hours in Rawalpindi’s harsh conditions prove this isn’t just machinery—it’s mission-critical infrastructure.

5. Smart Financial Wins

With today’s 7.9% green financing rates (vs. 15%+ for conventional loans), our clients recover investments in 18–30 months. The Islamabad Tech Park case shows PKR 3.2M /year saved just on avoided downtime—imagine what that means for your bottom line.

6. A Partner Who Delivers

While others talk, we act:

53-day installations (Karachi SEZ) vs. industry’s 90+ days

Live drone monitoring so you see progress hourly

Milestone-based payments—you pay only for results

“The energy crisis won’t wait. Neither should you.”

Would you like a same-day feasibility estimate? Share your monthly kWh usage, and we’ll email a customized ROI analysis within 4 hours.